Our Proprietary Technology

Innovation in the pursuit of optical excellence.

For well over half a century Tamron has been recognised as a leading innovator in cutting-edge optical design, and acclaimed for its mastery of the underlying mechanical and electronic technologies that make today’s amazing lenses possible. Developing practical, compact, easy-to-use lightweight zoom lenses with incredible zoom ranges, apertures and close focusing ability, that also deliver world-class imaging performance, is not simply a matter of refining existing ideas — it entails creative thinking at the highest level. Here is a definitive list of the design concepts used in today’s state-of-the-art Tamron lenses.

Optical Technology

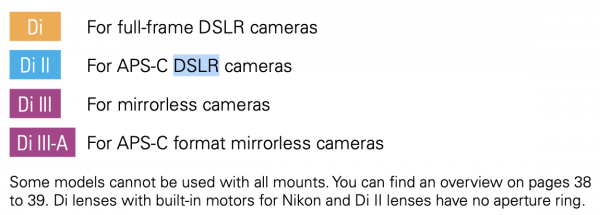

The designation Di (Digitally Integrated) refers to a lens developed specially for the exacting requirements of digital cameras. Please ensure when purchasing that the lens has the correct mount for your camera system.

The TAMRON SP (Superior Performance) series is a line of ultra-high-performance lenses designed and manufactured to the exacting specifications demanded by professionals and others who require the highest possible image quality. In creating SP lenses, TAMRON’s optical designers put their foremost priority on achieving superior performance parameters—they are all designed to a higher standard with little regard for cost constraints.

XR glass use glass materials with a higher refractive index than regular optical

lenses. By placing XR glass elements in the front group of a lens, the overall optical length can be kept shorter.

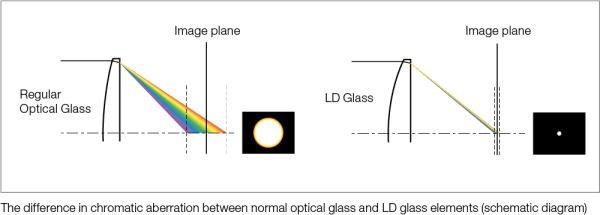

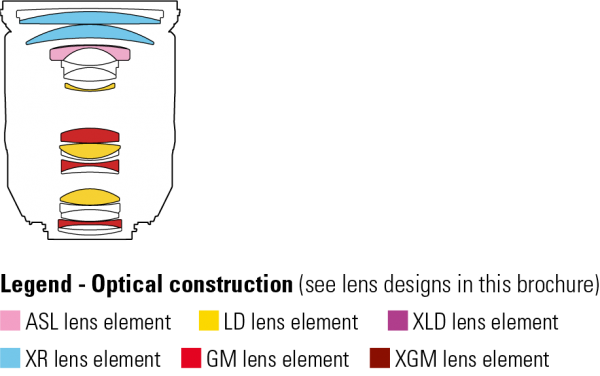

LD lens elements help reduce chromatic aberrations. A glass with an extremely low dispersion index has less of a tendency to separate (diffract) a ray of light into a rainbow of colours. This characteristic allows the lens designer to effectively compensate for chromatic and lateral chromatic aberration, which are a particular problem at wide-angle and telephoto focal lengths.

XLD lens elements made from specialized ultra-high-grade glass allow TAMRON lens designers to achieve much greater control over chromatic aberration and magnification aberrations. In combination with LD, XLD lens elements contribute to achieving sophisticated lenses that deliver the highest possible contrast, the finest detail, and superior imaging performance throughout the entire zoom range.

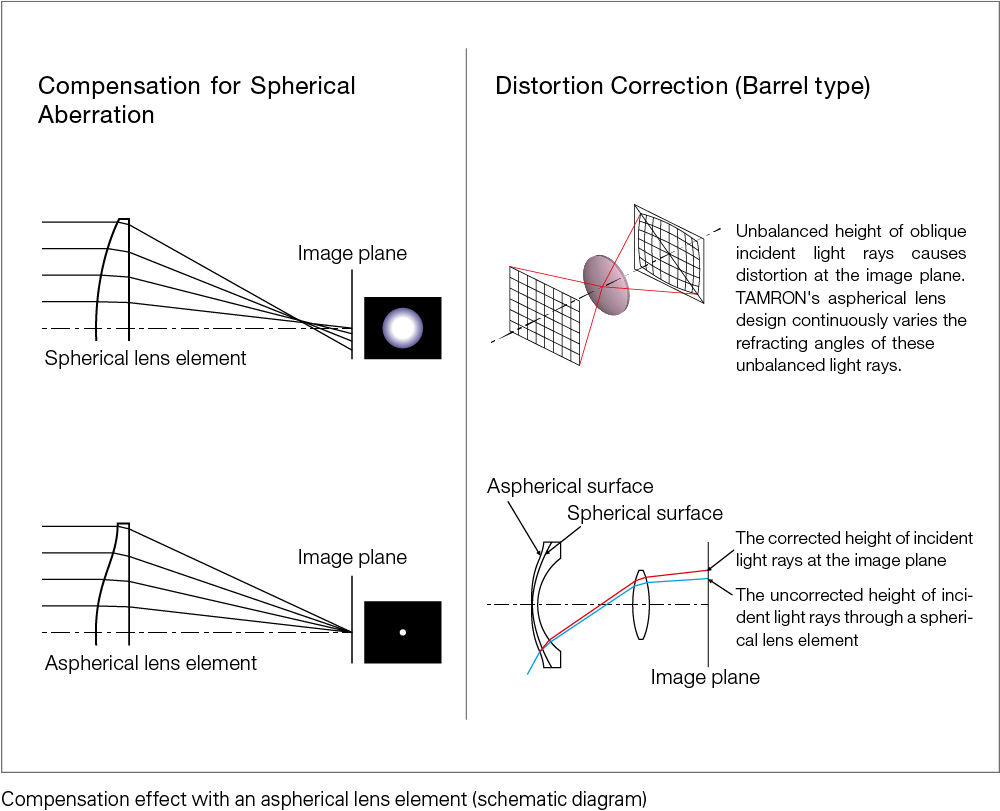

TAMRON uses several Hybrid Aspherical lens elements and other lenses bearing the aspherical designation. These innovative optics allow us to achieve the ultimate in image quality and produce lenses that offer remarkable zoom ranges in extraordinarily compact packages. Through the effective application of Hybrid Aspherical, one lens element can take the place of multiple elements without compromising performance. This is what allows us to produce remarkably compact long-range lenses that deliver a uniformly high level of image quality.

GM and XGM lens elements are capable of efficiently correcting aberrations in the angle of view that changes significantly with an ultra wide-angle zoom lens. It has an especially significant impact on minimizing distortion and enhancing the sharpness of the image at its periphery. Furthermore, the molded-glass manufacturing method allows the fabrication of a wider range of lens shapes than the composite aspherical lens method. Moreover, XGM also effectively controls aberrations and reduces total lens size.

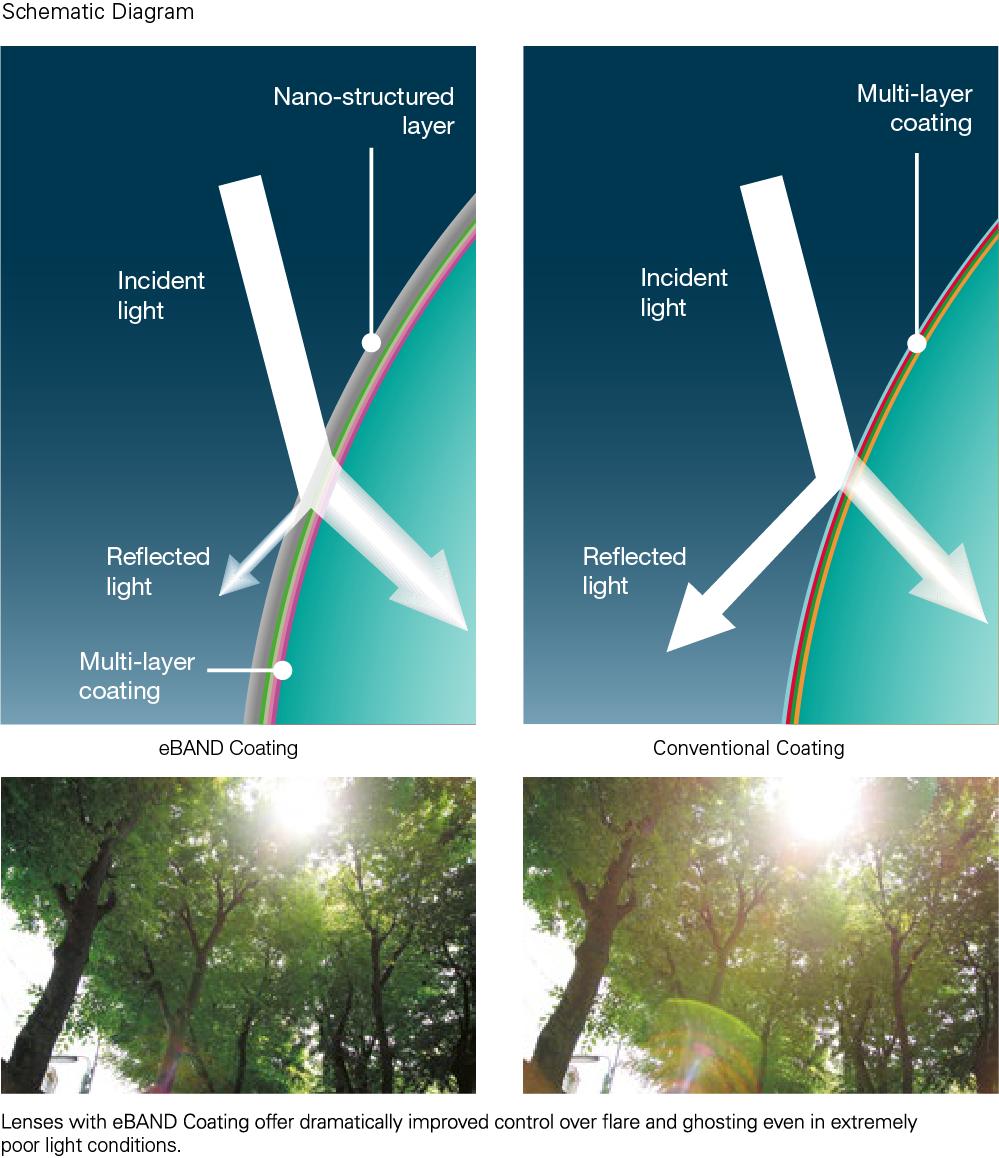

The eBAND Coating consists of a wafer-thin nanostructure (1 nm = 1/1,000,000 mm) with an extremely low refractive index. In combination with the underlying multi-coating, an outstanding anti-reflection effect is achieved.

TAMRON uses advanced multi-coating techniques to suppress reflections and light dispersion on lens element surfaces, resulting in reduced light transmission and may cause ghosting and flare images. Plus, the advanced BBAR-G2 Coating has been used since 2019.

IF provides practical benefits to photographers, including a non-rotating front filter ring that facilitates the positioning of polarizing and graduated filters, and more predictable handling because the lens length does not change during focusing. Even more important, TAMRON’s IF system provides a much closer MOD throughout its entire focusing range. In addition, IF improves optical performance by minimizing illumination loss at the corners of the image field (vignetting), and helps to suppress other aberrations that become more troublesome at different focusing positions.

ZL is a simple convenience feature that prevents undesired extension (creep) of the lens barrel when carrying the camera/lens unit on a neck strap. This enhances responsiveness in the field and helps protect the lens.

This mechanism quickly locks or unlocks the zoom at any position simply by sliding the zoom ring. Photographers can shoot from any angle without the zoom extending unintentionally.

*SP 150-600mm F5-6.3 G2 (Model A022), 150-500mm F5-6.7 (Model A057)

The lens hood is equipped with a locking mechanism, which prevents detachment due to unintentional contact during use.

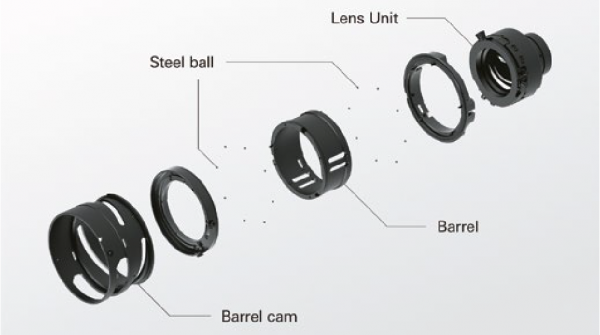

The Multiple-Cam Zoom Mechanism is an original TAMRON design that incorporates several precision cams cut into a single cylindrical surface using high-tech automated machinery. This key component enables zoom lens barrels to be extended and retracted effortlessly, achieving commendably compact dimensions at the wide-angle settings while holding precise extension at telephoto settings.

TAMRON’s Integrated Focus Cam is a precision mechanical component that optimizes the coordinated movement of the IF system with the Multiple-Cam Zoom Mechanism. This ingenious Focus Cam is designed to ensure seamless and precise positioning of all the highly sophisticated internal elements within the lens and coordinate them with the convenient external zoom and focus controls that comprise the user interface.

To ensure the highest levels of performance and durability without adding additional weight, TAMRON all-in-one zoom lenses make extensive use of engineering plastic (polycarbonate) materials in many critical mechanical components of the lens. Indeed, polycarbonate of this caliber is the material of choice whenever we produce high-precision components that require the strength to withstand rigorous use.

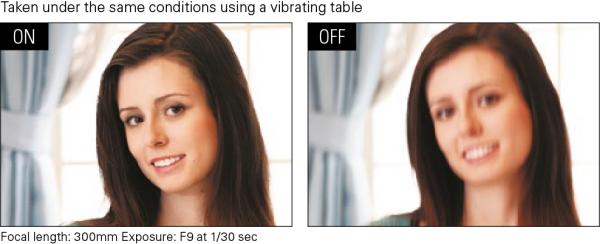

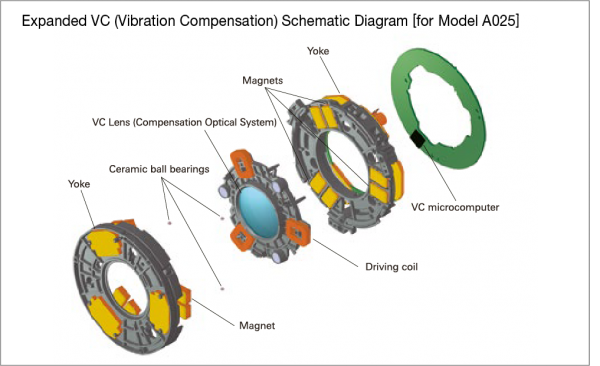

TAMRON’s unique VC mechanism uses a proprietary actuator and algorithms to deliver an extremely stable viewfinder image with excellent tracking. The mechanism uses a three-coil system to electromagnetically drive the lens element that compensates for vibration, which glides smoothly on three balls with little friction. This simple mechanical structure is one of the secrets to TAMRON’s compact lenses.

USD is an ingeniously upgraded AF drive system to deliver the extraordinary autofocusing speed and precision needed to capture every nuance of high- speed sports action, along with virtually noiseless operation. Based on advanced motor technology and newly developed software, it employs a piezoelectric ceramic element to generate two high-frequency ultrasonic vibrations on the motor’s stator ring. This in turn causes the adjacent metallic rotor to rotate by means of deflective traveling waves when the voltage of a specific frequency is applied.

This energy-saving HLD motor generates outstanding drive torque, so focusing is precise and quiet. Because of its small size and arched shape, the HLD motor doesn’t take up much space, which meant the lens could be designed to be even more compact.

OSD module allows silent focusing. This makes the lens ideal for situations in which absolute silence is needed during photography. The AF also reacts very quickly and focuses precisely.

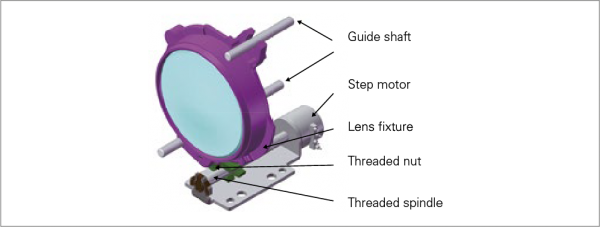

RXD is a stepping motor with a drive element that precisely controls the angle of rotation. A sensor continuously determines the lens’s current focus setting, achieving quick and precise focusing that also allows videographers to keep moving objects in focus continually. All the while, the AF works so quietly that there is no interference in the video from focusing noise.

VXD is a linear motor focus mechanism for stunningly fast and accurate auto-focusing. Focus tracking has also been vastly improved during sports and racing photography. This ensures that those powerful moments are never missed, whether shooting still photos or video. With the excellent quietness that is characteristic of linear motor systems, the AF is ideal for shooting in low-noise environments.

Thanks to the Dynamic Rolling-cam mechanism, which operates the heavy focusing unit of the fast-aperture with high speed and accuracy, TAMRON has succeeded in minimizing the drive load placed on the focus lens component. This breakthrough ensures stable AF operating performance and improves reliability even under the harsh shooting conditions of professional use, including high and low-temperature extremes.

This is a microprocessing unit incorporating two different microchips. Two separate processor units mean that digital signals from the VC image stabilization and autofocus are processed separately at maximum speed. This means, for example, that commands from the camera and AF motor can be interpreted at lightning speed and implemented precisely.

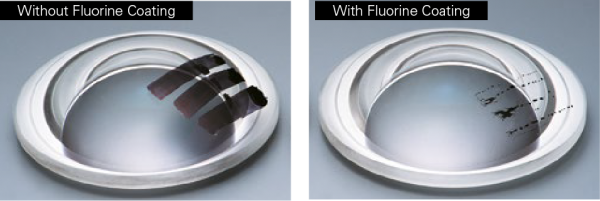

Fluorine Coating was developed for optical systems in industrial production. It provides long-term protection to the front lens against oil and water. Any soiling won’t stick to the surface – you will be able to wipe it away easily.

Moisture-Proof and Dust-Resistant Construction has been improved to an exceptionally high standard in lens protection, preventing any intrusion of dirt, dust, or raindrops. A rubber seal protects each switch on the lens, and the sealant material is applied to the mechanical interface between the focus ring and the lens housing. The construction further expands shooting opportunities, ensuring reliability even in harsh, windy conditions and immediately after rainfall.

For greater protection when shooting outdoors, leak-resistant seals throughout the lens barrel help protect your equipment.